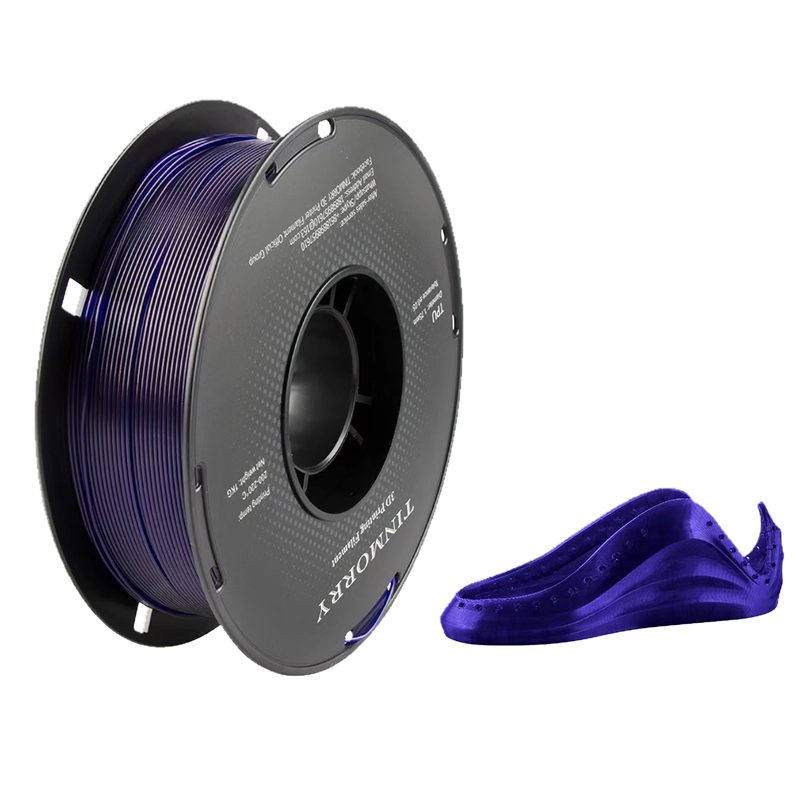

TPU 3D Printer Filament

$6.50 – $7.00Price range: $6.50 through $7.00Per quantity

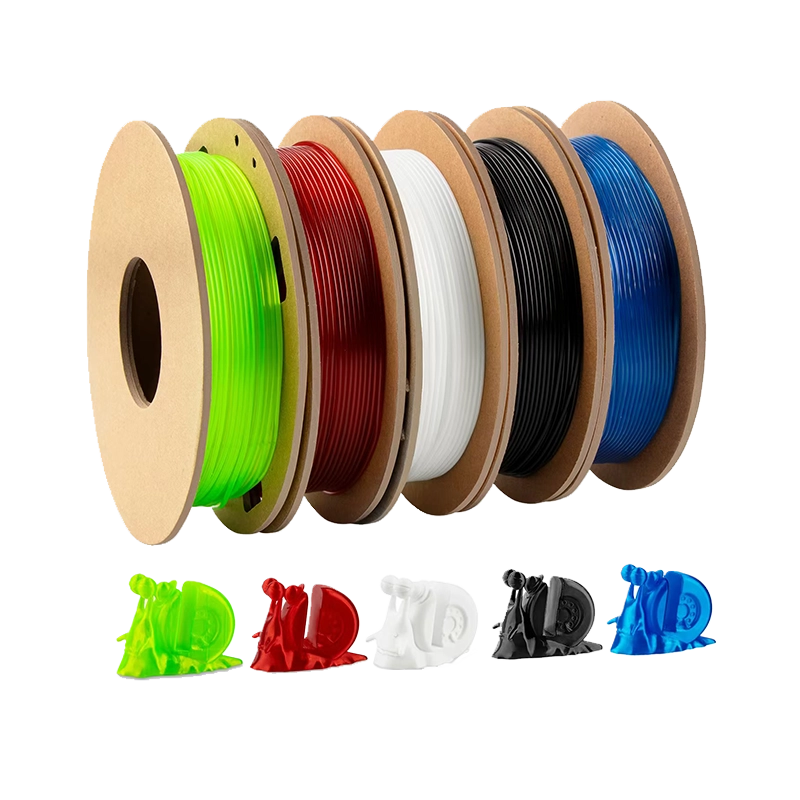

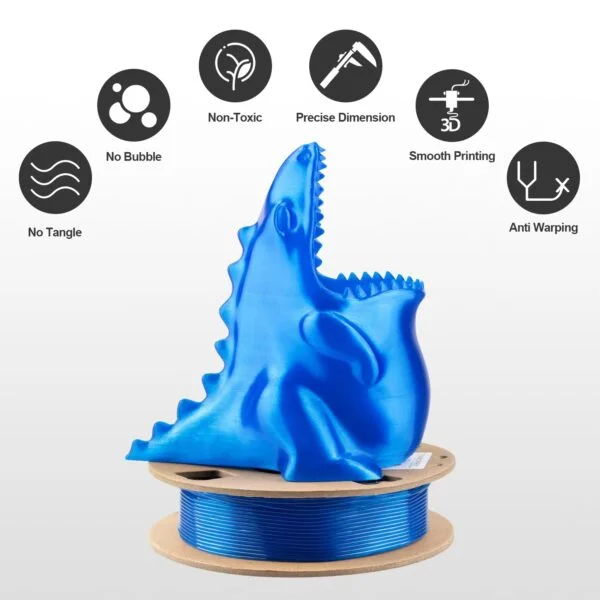

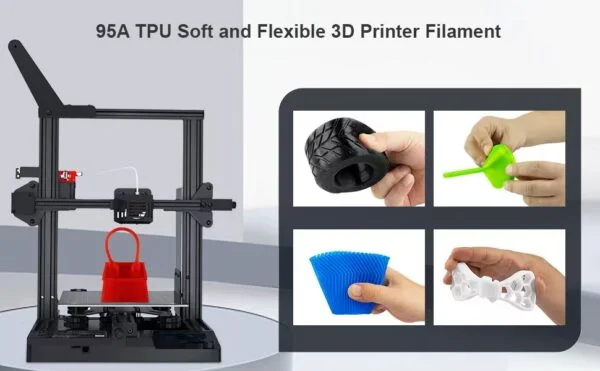

TINMORRY’s TPU (Thermoplastic Polyurethane) 95A filament is a versatile and flexible material designed for high-performance applications in a wide range of industries. With excellent elasticity, superior impact resistance, and strong abrasion tolerance, it is well-suited for projects that require both mechanical strength and flexibility. Whether you’re working on wearables, mechanical components, or cushioning prototypes, this material adapts seamlessly to both simple and complex geometries. Its balanced shore hardness and smooth extrusion behavior make it one of the best TPU filament choices for professionals seeking both reliability and high-quality results.

For more information related to product and prices, please Click Here.