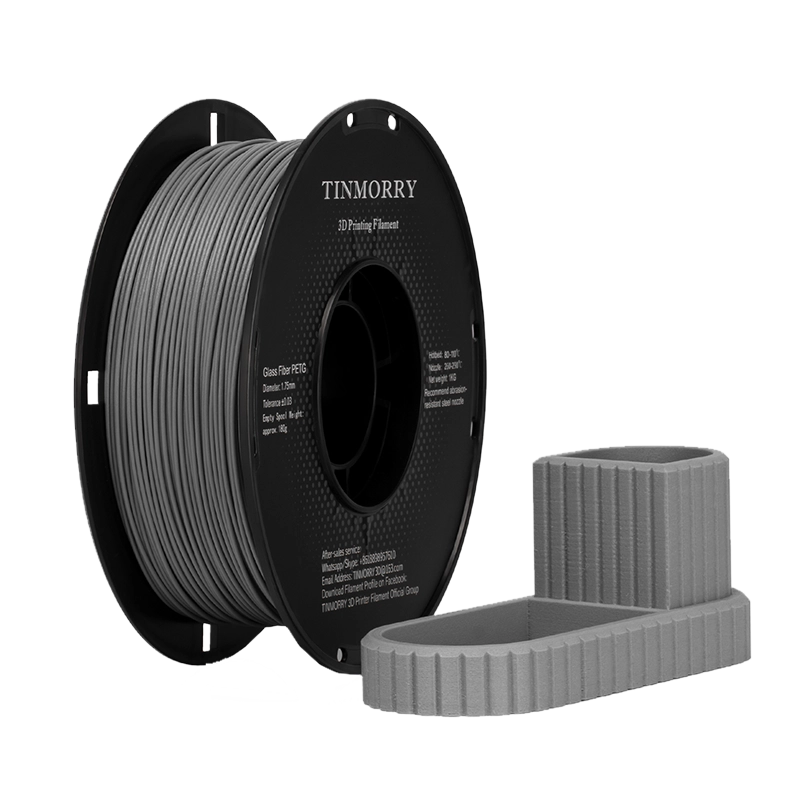

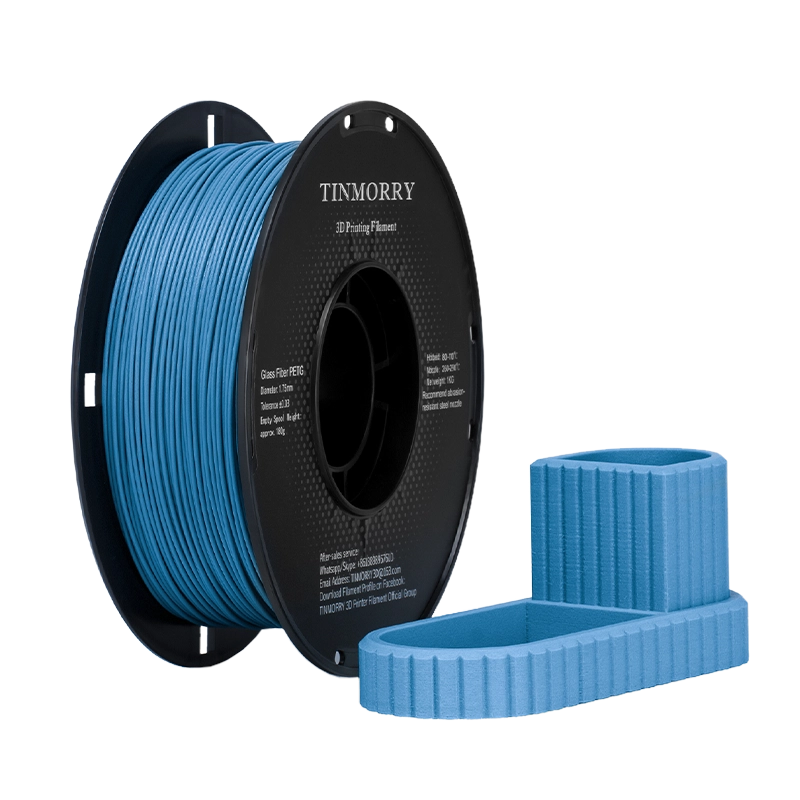

PETG-Marble

$5.50Per quantity

TINMORRY’s marble PETG filament offers a stunning combination of functionality and aesthetics. By blending durability with a premium, marble-like surface effect, this filament is ideal for projects that require high visual appeal alongside robust performance. If you’re ready to elevate your 3D printing results, it’s time to select a material that combines both beauty and versatility in your creations.

For more information related to product and prices, please Click Here.