What Sets TINMORRY PETG-GF Apart from Others

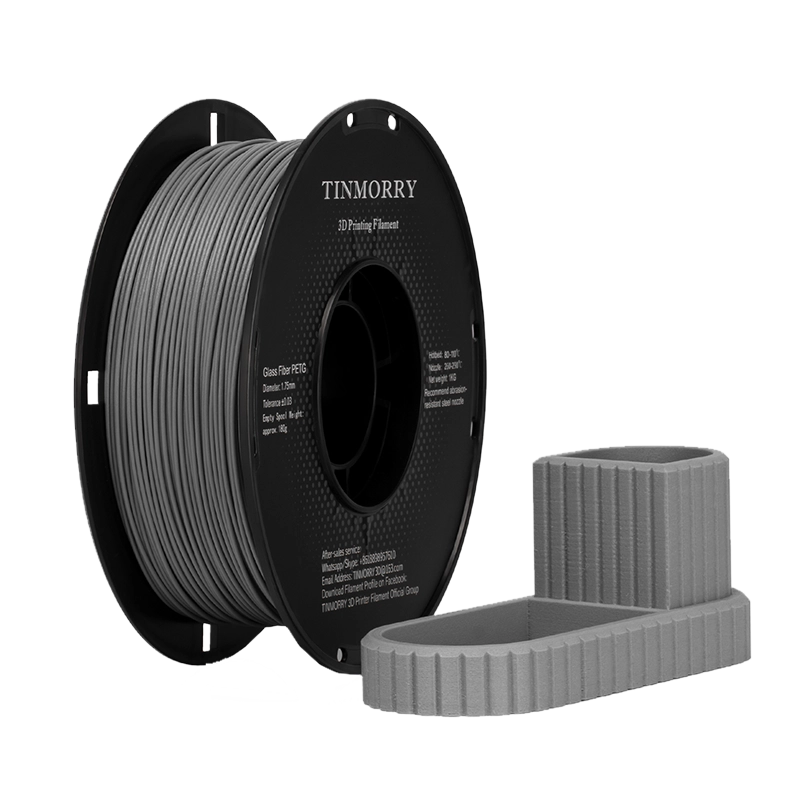

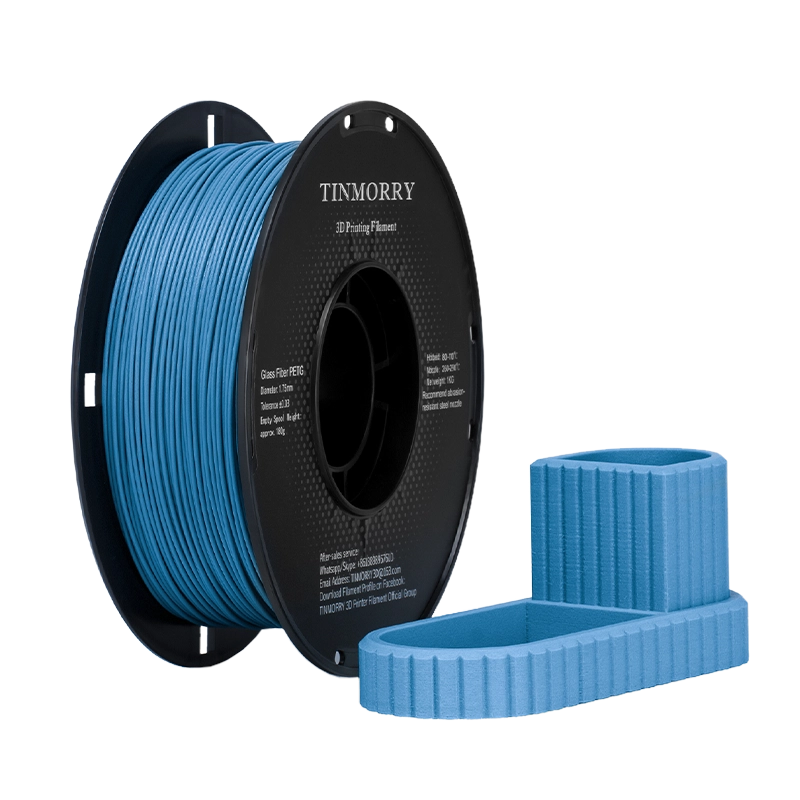

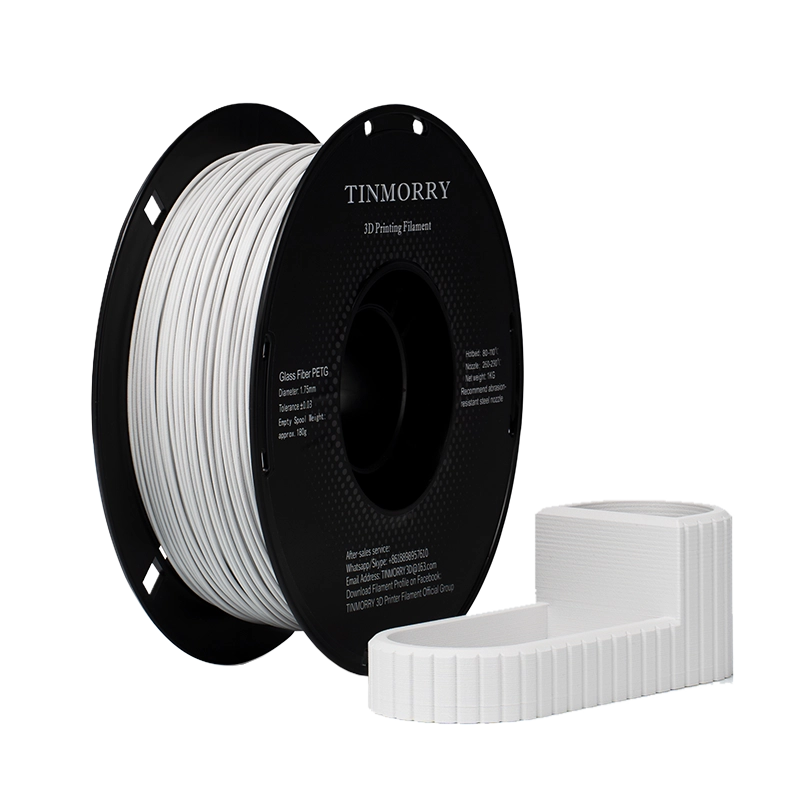

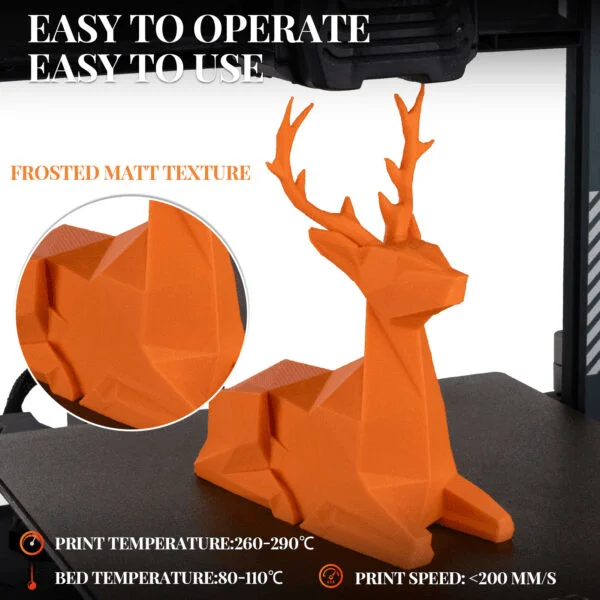

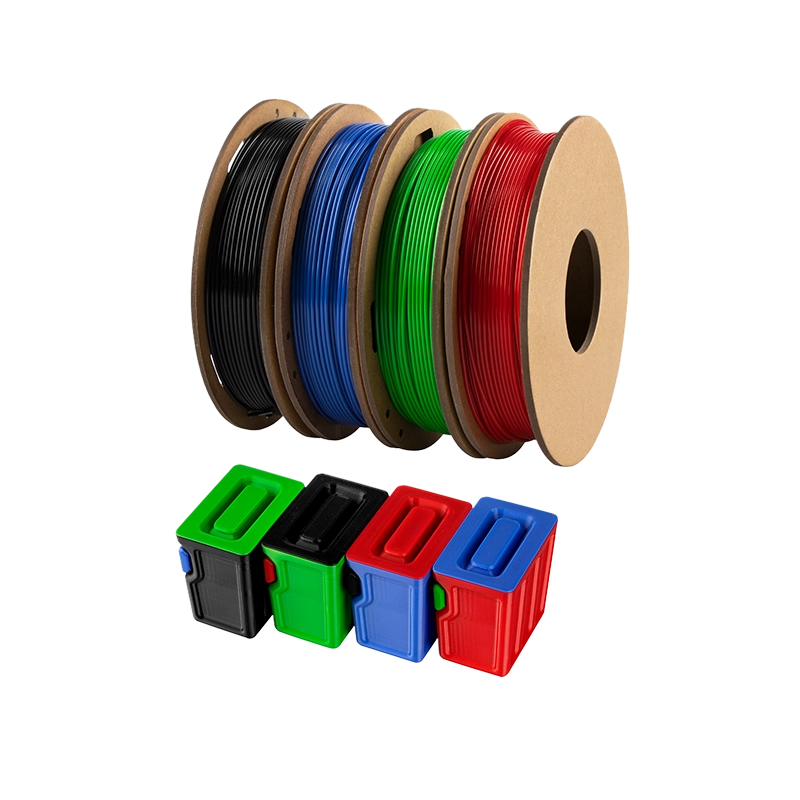

TINMORRY PETG glass fiber filament is a premium composite reinforced to deliver increased rigidity, reduced warping, and consistent print quality. Its unique formulation ensures minimal shrinkage while producing strong, functional parts with a frosted surface texture. Ideal for projects where structural integrity and heat tolerance are critical, it’s suited for industries ranging from automotive to protective equipment.

Whether you’re working on prototypes or performance-based parts, our glass fiber 3D printer filament ensures superior durability and finish. With PETG-GF, you’re equipped to tackle complex projects with confidence and precision.