What Sets TINMORRY PETG-CF Apart from Others

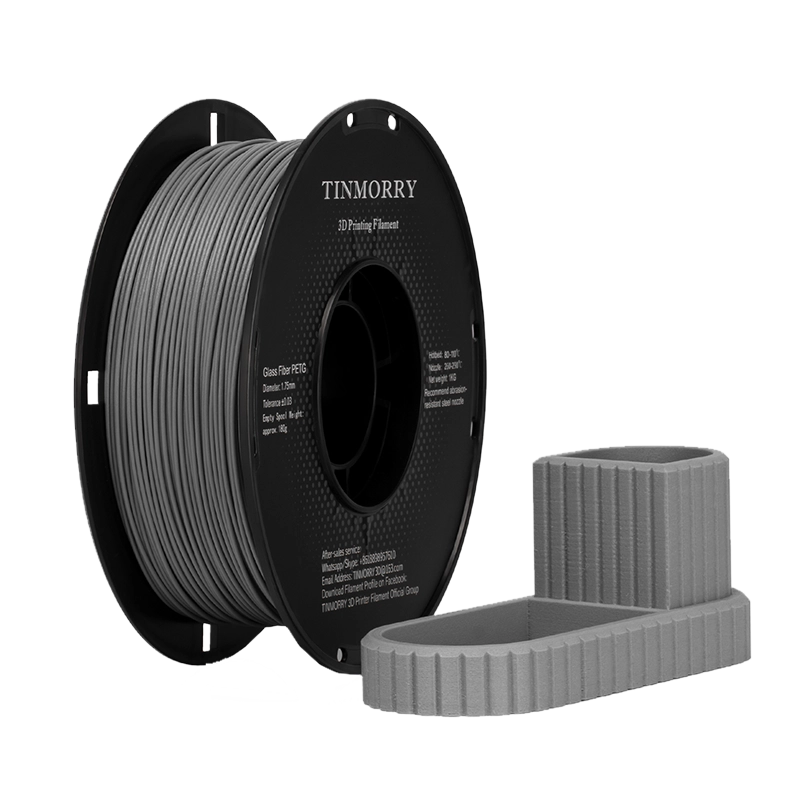

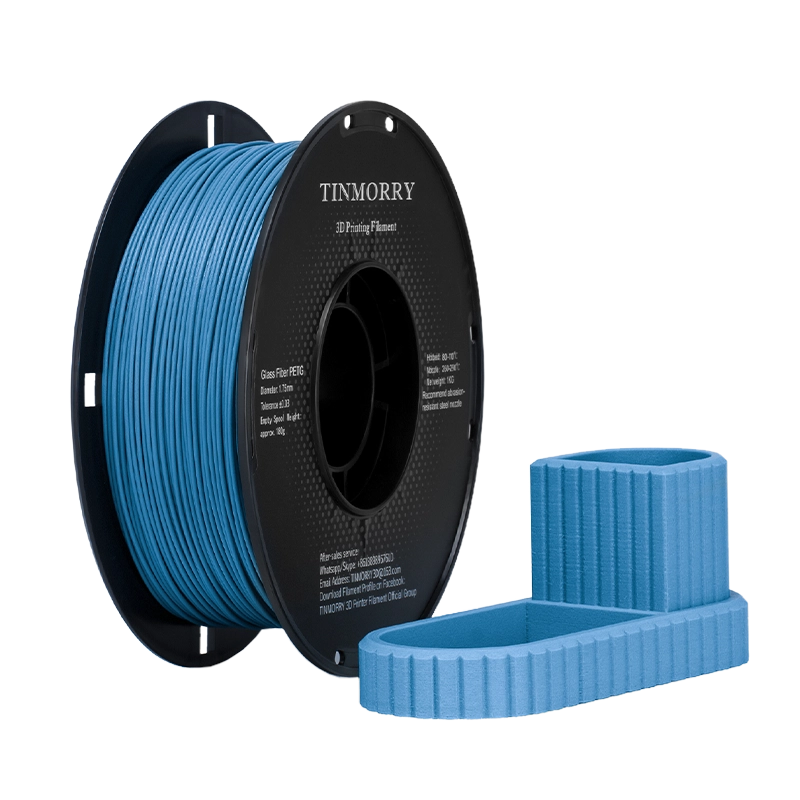

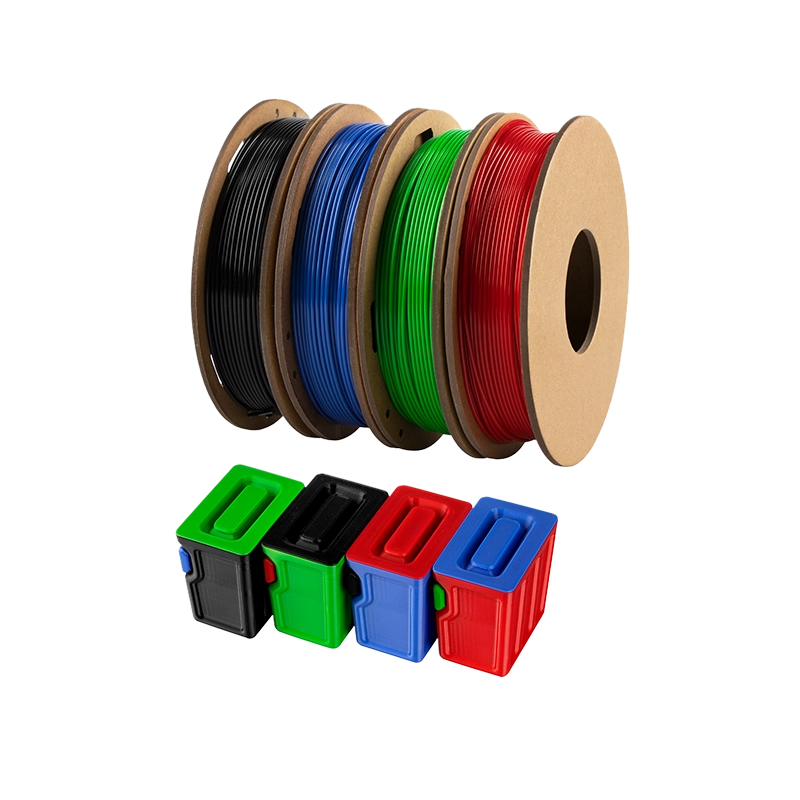

TINMORRY’s carbon fiber PETG is a composite material that offers the best of both worlds – the easy printability of PETG with the added strength and rigidity of carbon Fibers. Unlike conventional options, this material infused with carbon Fiber provides exceptional performance while reducing the likelihood of nozzle clogs and print failures.

With material designed for high-speed printing, you can achieve fast, precise prints without sacrificing strength. Whether you’re creating complex mechanical parts or prototypes, PETG carbon fiber filament from TINMORRY is a superior choice for any high-performance 3D printing application.