What Sets TINMORRY PP-CF Apart from Others

This product stands out for its ability to handle high-performance requirements across multiple industries.

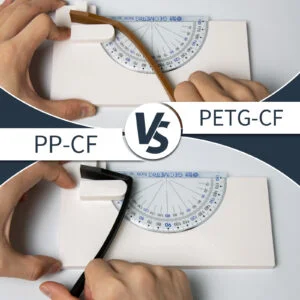

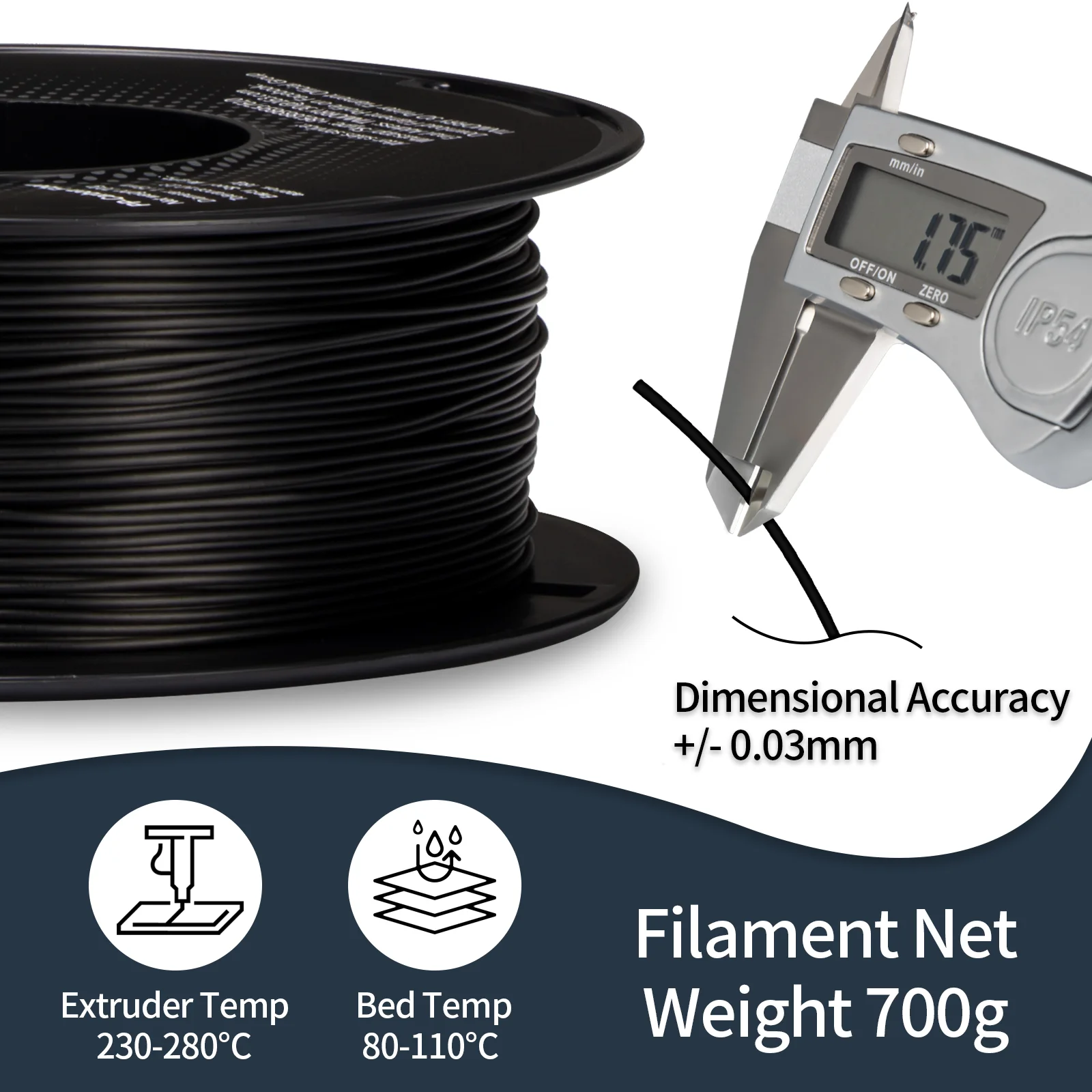

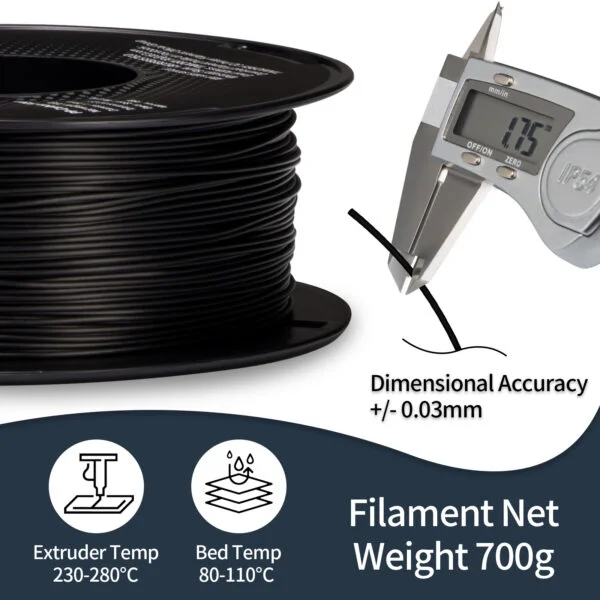

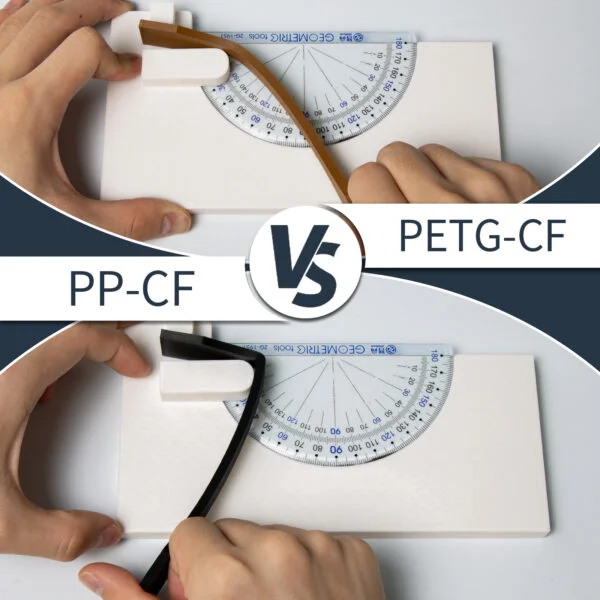

TINMORRY’s PP-CF offers the best of both worlds: the lightweight, easy-to-print properties of polypropylene combined with the added strength and stiffness from carbon fiber reinforcement. Unlike other carbon fiber 3D filament, it maintains its dimensional stability and excellent physical properties in extreme environments. Whether you’re producing lightweight structural components for aerospace or chemical-resistant parts for industrial use, this product offers a reliable solution for demanding applications.

That’s why professionals turn to TINMORRY PP-CF when consistency, durability, and precision are non-negotiable.