PET-CF (Carbon Fibre Reinforced PET) Filament

$25.00Per quantity

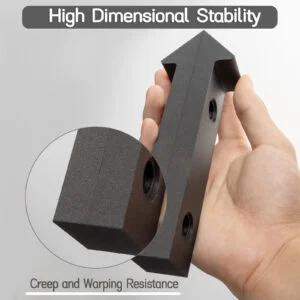

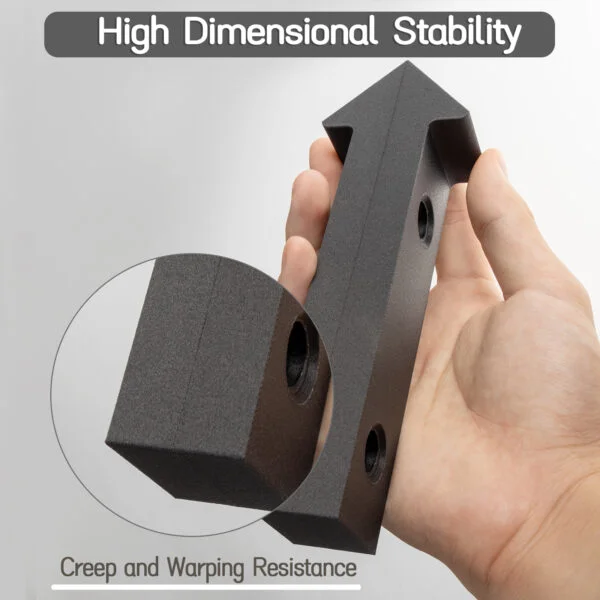

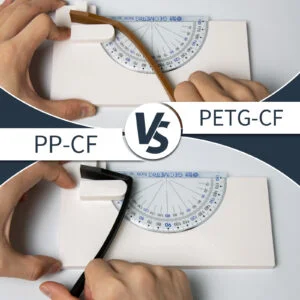

TINMORRY’s PET-CF filament is a high-performance 3D printing material that combines the durability of PET with the exceptional strength of chopped carbon fibers. Designed to meet the demands of professional-grade engineering, it offers enhanced mechanical properties, including increased rigidity, wear resistance, and overall durability. With its impressive thermal resistance and dimensional stability, it is perfect for complex applications where strength, precision, and reliability are crucial. For engineers and professionals seeking to produce advanced parts using a carbon fiber 3D printer filament, this filament delivers the performance required to excel in high-stress environments.

For more information related to product and prices, please Click Here.