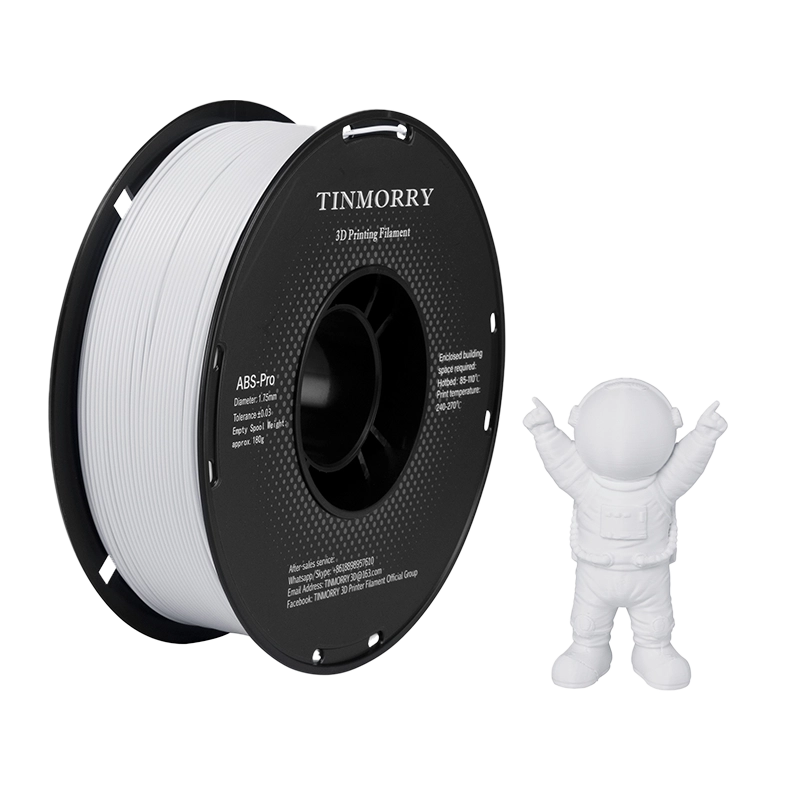

What Sets TINMORRY ABS Filament Apart from Others

TINMORRY’s ABS filament combines toughness, precision, and reliability to deliver top-notch results for your projects. Unlike other options on the market, this material is manufactured with strict quality controls to eliminate tangling, bubbling, or clogging during printing. Its exceptional impact strength and wear resistance make it a superior choice for demanding applications, while the vacuum-sealed packaging ensures that the material stays in perfect condition before use — ideal when you want to print ABS with consistency.

Whether you’re exploring industrial-grade solutions or simply looking for high-performing filament, TINMORRY offers one of the best ABS filament choices available. With its focus on reliability, strength, and smooth extrusion, this filament delivers results professionals can count on.