Discover the future of 3D printing with TINMORRY, your one-stop destination for high-quality 3D printer supplies. Whether you’re a hobbyist, professional, or industrial expert, we provide top-notch materials that redefine possibilities in additive manufacturing.

Industrial 3D Printer Filament Solutions for Enhanced Productivity

Carbon Fibre Reinforced Industrial Filaments

When it comes to creating durable and high-quality 3D prints, industrial 3D printer filament is the material of choice for professionals. Combining exceptional strength, toughness, and printability, these industrial-grade materials are built to withstand harsh environments and meet the demands of complex applications. Whether you’re crafting automotive components, prototyping high-strength tools, or building machinery parts, this filament delivers reliable and long-lasting results.

What Makes Industrial Filaments Special?

Industrial filament stands out due to its superior durability, mechanical strength, and precision. TINMORRY’s Industrial Filament is engineered for harsh performance conditions, offering excellent layer bonding, impact resistance, and tensile strength. These properties make it perfect for robust, functional parts across demanding sectors. Professionals seeking consistency, strength, and accuracy in their prints can rely on this material for mission-critical projects involving industrial 3D printing with filament.

Properties of Industrial Filaments

This filament is known for its toughness and resistance to cracking, even under mechanical stress. It performs well in high temperatures, making it suitable for sectors such as automotive, aerospace, and manufacturing. With stable extrusion, strong bed adhesion, and reduced warping or clogging, it ensures smooth print runs. Additionally, its dimensional accuracy guarantees consistency in detailed prototypes and production-grade components.

Applications

The strength and versatility of this material make it ideal for:

- Automotive Components: Withstand stress, vibration, and high-heat environments

- Aerospace Parts: Lightweight yet structurally sound for extreme conditions

- Functional Prototypes: Mimic real-world product performance

- Machinery Parts: Precise, durable parts for mechanical systems

- Consumer Electronics: Strong structural parts for devices under constant use

Optimal Printing Settings

For best results, use a nozzle temperature of 220°C-250°C and bed temperature between 70°C-90°C. A moderate print speed of 40–60mm/s ensures accurate extrusion. To avoid quality degradation, dry the filament at 70°C for 4-6 hours and store it in a sealed container with desiccant.

Why Industrial Filaments?

TINMORRY’s Industrial Filament offers superior mechanical properties, heat resistance, and precision, making it ideal for professionals in engineering, manufacturing, and design. From rugged prototypes to high-performance end-use parts, this filament empowers users to bring their toughest ideas to life with confidence.

FAQs

1. What is industrial 3d printer filament and how is it different from standard filament?

Industrial 3d printer filament refers to high-performance materials designed for specialized applications such as aerospace, automotive, and manufacturing. Unlike standard PLA or ABS, industrial filaments like PEEK, PEI (Ultem), carbon fiber-infused nylon, and PPSU provide exceptional strength, thermal stability, and chemical resistance. These filaments often require high-temperature 3D printers with enclosed chambers and hardened nozzles.

2. What are the common types of industrial 3d filament used in professional manufacturing?

When users search for industrial 3d filament, they are generally looking to compare material properties and select the right filament for prototyping, tooling, or end-use parts in an industrial setting.

Popular industrial 3d filament types include:

- PEEK (Polyether Ether Ketone): Extremely strong and heat-resistant.

- PEI/Ultem: High heat deflection and flame resistance.

- Carbon Fiber Nylon: Lightweight, stiff, and durable.

- Polycarbonate (PC): Impact-resistant and strong.

- PPSU: Excellent chemical resistance and sterilization compatibility.

These filaments are ideal for demanding engineering applications and often used in regulated industries where performance and reliability are critical.

3. What should I consider when choosing industrial 3d printer filament for my application?

When selecting industrial 3d printer filament, consider:

- Mechanical properties (tensile strength, flexibility, impact resistance)

- Thermal resistance (operating and print temperatures)

- Chemical resistance (exposure to solvents, acids, or bases)

- Compatibility with your 3D printer (extruder temperature, heated bed, enclosure)

- Application needs (prototyping vs. end-use parts, regulatory requirements)

Choosing the right filament ensures optimal performance and longevity of printed parts in industrial settings

4. What types of applications benefit most from “industrial 3d printer filament”?

Industrial 3d printer filament is indispensable in applications requiring high-performance, durable, and reliable parts. Key sectors and uses include:

- Aerospace: Lightweight, high-strength components, prototypes for aircraft interiors, tooling, and spare parts that can withstand extreme conditions.

- Automotive: Functional prototypes, jigs, fixtures, end-use parts under the hood

- (e.g., engine components, brackets), and custom interior elements.

- Medical & Dental: Custom prosthetics, anatomical models for surgical planning, sterilization-ready medical devices, and biocompatible implants (with specific certifications).

- Manufacturing & Tooling: Custom jigs, fixtures, manufacturing aids, robot end-effectors, and short-run production tools.

- Defense & Robotics: Durable parts for unmanned systems, protective components, and specialized equipment.

- Electronics: ESD-safe enclosures, insulating parts, and components that require high heat resistance.

- Oil & Gas: Parts requiring resistance to harsh chemicals, high pressures, and extreme temperatures.

- Consumer Goods (High-End): Durable, custom components for premium products where traditional manufacturing is less cost-effective for low volumes.

Our Industrial Filament Products

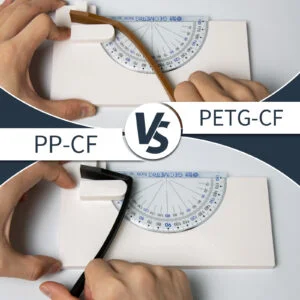

PET-CF (Carbon Fibre Reinforced PET) Filament

$25.00Per quantity

PP-CF (Carbon Fibre Reinforced Polypropylene) Filament

$17.00Per quantity

PAHT-CF Carbon Fiber Filament

$42.00Per quantity