Discover the future of 3D printing with TINMORRY, your one-stop destination for high-quality 3D printer supplies. Whether you’re a hobbyist, professional, or industrial expert, we provide top-notch materials that redefine possibilities in additive manufacturing.

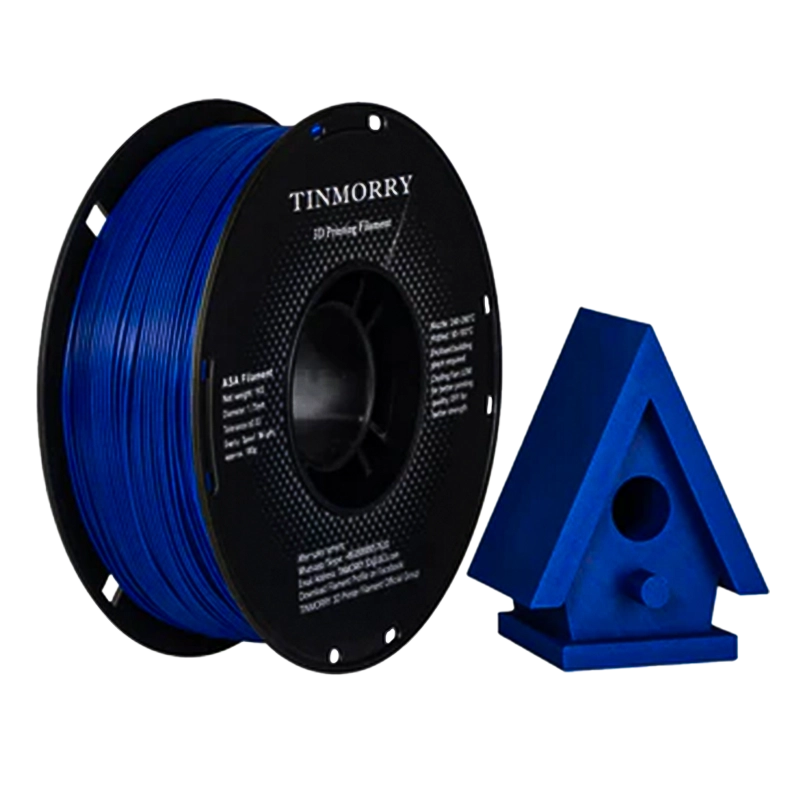

Achieve High-Impact Resistance with ASA Filament

ASA Filaments

ASA filament (Acrylonitrile Styrene Acrylate) is a popular material in 3D printing, known for its durability and resistance to environmental factors. TINMORRY’s version offers these benefits, making it suitable for a wide range of demanding applications, especially where strength and weather resistance are essential.

What Makes ASA Filament Special?

ASA stands out for its unique combination of toughness, UV resistance, and thermal stability, making it an ideal choice for both indoor and outdoor use. Unlike materials such as ABS, ASA 3D filament maintains its mechanical properties even when exposed to harsh elements like sunlight, rain, and temperature fluctuations. Its superior UV stability ensures prints retain their color and structure over time—perfect for long-lasting outdoor products.

Properties of ASA Filament

This filament is valued for its durability and ability to resist UV and weather conditions, making it particularly effective for outdoor applications. It also offers high-impact resistance, consistent performance across a wide range of temperatures, and excellent chemical resistance. TINMORRY’s formulation helps reduce common printing issues, such as warping or shrinking, and emits fewer odors than comparable materials, thereby improving the overall printing experience.

Applications of ASA Filament

- Outdoor Signage: Its UV resistance makes it excellent for signs that need to withstand sunlight and weather exposure.

- Automotive Parts: Its thermal stability and strength make it ideal for vehicle components.

- Sporting Goods: With toughness and environmental resistance, it’s well-suited for manufacturing outdoor sports equipment.

Optimal Printing Settings

For optimal results, set the extruder temperature to between 240°C and 260°C and the heated bed to between 90°C and 110°C. Using an enclosed print chamber helps maintain temperature consistency and minimizes warping. To improve bed adhesion, consider using a PEI sheet or glue stick.

Why ASA Filament?

TINMORRY’s ASA 3D printer filament combines durability, weather resistance, and ease of printing, making it a go-to material for both industrial and outdoor 3D printing needs. By following proper printing practices, users can expect consistently high-quality results across various projects.

FAQs

1. What is ASA filament and what are its main properties?

ASA filament (acrylonitrile styrene acrylate) is a technical 3D printing material known for its high UV resistance, weather resistance, and durability. It is ideal for outdoor applications, offers strong impact resistance, and is more chemically resistant than many other filaments. ASA is similar to ABS but features improved mechanical properties and superior aesthetics. However, it requires higher printing temperatures and careful handling to avoid warping and exposure to fumes

2.Why should I choose asa 3d printer filament over other materials?

ASA 3d printer filament offers superior UV and weather resistance compared to ABS, making it ideal for outdoor and high-stress applications. It also provides better mechanical properties, higher impact strength, and improved aesthetics. These features make it a preferred choice for users needing durable, long-lasting prints exposed to the elements.

3. What is asa 3d printing filament made of?

ASA 3D printing filament is made from acrylonitrile styrene acrylate, a terpolymer synthesized from acrylonitrile, styrene, and acrylate. Each component contributes to the filament’s gloss, chemical resistance, impact resistance, and durability.

4. What are the typical use cases for asa 3d printing filament?

Common use cases of ASA 3D Printing Filament include automotive components, outdoor fixtures, electrical housings, and functional prototypes where strength, weather resistance, and durability are required.

Our ASA Filament Products

ASA 3D Printer Filament

$7.80Per quantity